-40%

Master 1/35 M1919 Browning .30 Cal Machine Gun Barrels Late w/Cylindr. GM-35-005

$ 8.18

- Description

- Size Guide

Description

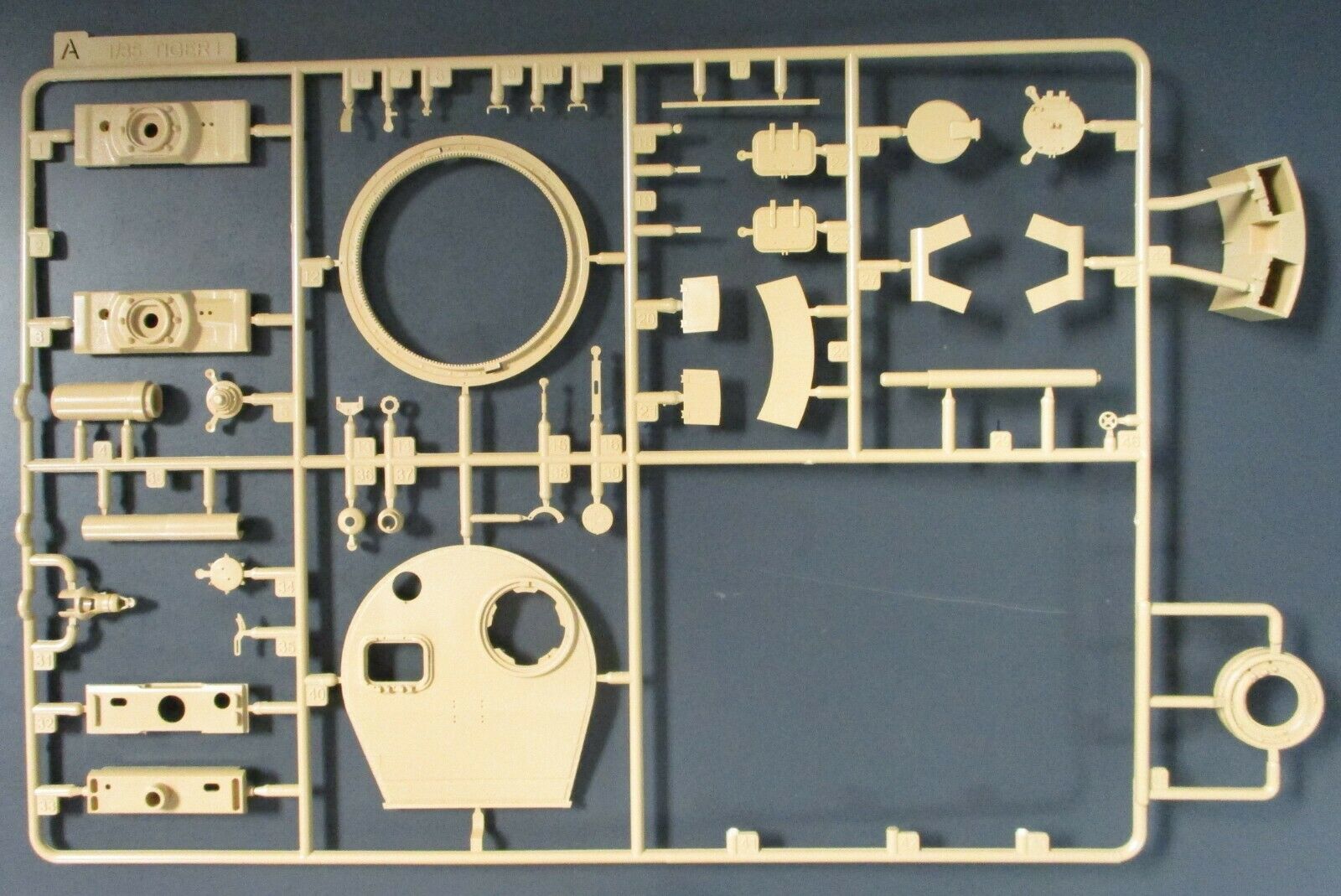

Master Model 1/35 M1919 Browning US .30 caliber Machine Gun Barrels (Late type with one piece Cylindirical Muzzle) (2 barrels) GM-35-005Brand new!

This is a

metal

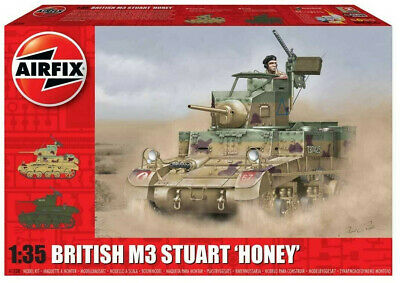

AFV / diorama accessory kit from Master Model. Kit consists of unassembled and unpainted metal parts, parts are shown in first picture. Built and painted one's picture is for reference only and put for you to enjoy fine detailing of this kit.

The M1919 Browning is a .30 caliber medium machine gun widely used during the 20th century, especially during World War II, the Korean War, and the Vietnam War. It was used as a light infantry, coaxial, mounter, aircraft, and anti-aircraft weapon by US and many other coutries.

The set includes two turned brass barrels with drilled cooling jackets. Fits all 1/35 scale models. It is very simple to use in your model, and makes it extremely realistic. Simply cut off the original plastic barrel and drill a hole in the remaining plastic part and insert the metal barrel using Cyanoacrylate adhesive.

Important!

This item is unassembled and unpainted. All extra model kit(s) and figure(s) in the pictures are for illustrative purposes only, and they are

not

included.

About Master Model:

Master Model is a Polish company specialized in producing high quality metal turned barrels and metal accessories for scale model aircraft, ships and armor. They have a wide selection of brass barrels, pitot tubes and radar aerial assemblies in various scales. The company is owned by Piotr Czerkasow, a mechanical engineer who created Master Model with a passion for making perfect models that are true reflection of real originals. The accuracy and level of detail result in a superb realistic model.

One area where injection molded plastic struggles to provide detail and scale thickness are the Pitots found on most jets, in particular ones having unusual elements present. Master Model have made one of their tasks to provide these items in resin and metal. The finesse and detail level of these parts can only be dreamt of in injection molded plastic. Having no clean up required is an added bonus to reduced risk of damage to the finish of the parts, as they are less likely to be broken.